Crib Screw Measurement Reference

The wording how to measure crib screws correctly appears frequently in search activity tied to identifying crib hardware after parts have been separated or mixed. This phrasing is typically associated with locating size differences in manufacturer specifications rather than describing an active process. Small variations in screw length or thread size are often noted in product materials, as even minor differences can affect how components align once hardware is returned to a crib frame.

The wording how to measure crib screws correctly is commonly associated with crib hardware identification following disassembly or long-term storage. In manufacturer materials, the phrase how to measure crib screws correctly functions as a reference label tied to dimensional identification rather than an action-based description. Product documentation frequently distinguishes screw types using small dimensional variations that are not always obvious without side-by-side comparison.

Manufacturer materials regularly list screw dimensions as part of broader hardware sets rather than as standalone items. As a result, crib screws are often referenced by measurement values, thread designation, and head configuration instead of by generic naming. This approach reflects standards information used to differentiate otherwise similar fasteners within a single crib model.

Why “how to measure crib screws correctly” appears in product materials

Crib hardware is produced as part of coordinated assemblies designed to align rails, corner posts, and mattress support frames. Screws, bolts, barrel nuts, and threaded inserts are typically engineered to function together within narrow tolerances defined during manufacturing. Product specifications often list exact measurements to distinguish fasteners used at different connection points, even when visual differences appear minimal.

In discontinued or older crib models, measurement references become more prominent because original packaging and labeled hardware kits may no longer be available. Manufacturer archives and secondary documentation frequently rely on dimensional identification when listing compatible parts. Measurement values serve as reference markers rather than operational instructions, supporting identification within product records.

For pages that organize crib hardware by manufacturer and part category, see the crib replacement parts hub, which groups fasteners according to published specifications.

Crib Screw Characteristics Listed in Standards Information

Product specifications for crib screws typically include several descriptive attributes. These attributes appear in manufacturer tables, diagrams, and parts lists rather than procedural text. The most frequently listed characteristics include overall length, threaded diameter, thread format, and head style. Each attribute functions as a classification marker rather than a usage directive.

Length values are usually expressed in millimeters and describe the distance between the underside of the head and the end of the threaded shaft. Diameter values identify the thickness of the threaded portion and are commonly associated with metric designations. Thread format descriptions distinguish metric threading from non-metric systems used in other furniture categories.

Head style descriptions appear alongside dimensional values to indicate how a fastener sits within brackets or rails. Common formats referenced in crib documentation include hex socket heads, Phillips heads, countersunk heads, and rounded button heads. These descriptions are included as identification data rather than functional guidance.

Dimensional References Found in Manufacturer Listings

Manufacturer listings often present crib screw dimensions in grouped tables that correspond to specific crib models or production runs. Within these listings, screws of similar appearance may carry different length or thread values based on their placement within the crib structure. Dimensional distinctions help differentiate fasteners intended for corner joints from those used along side rails or mattress support assemblies.

Metric sizing is commonly referenced in modern crib documentation. Thread designations such as M6 or M8 appear in parts lists as shorthand for diameter categories rather than as instructional labels. These designations function as classification terms within standards information published by manufacturers and distributors.

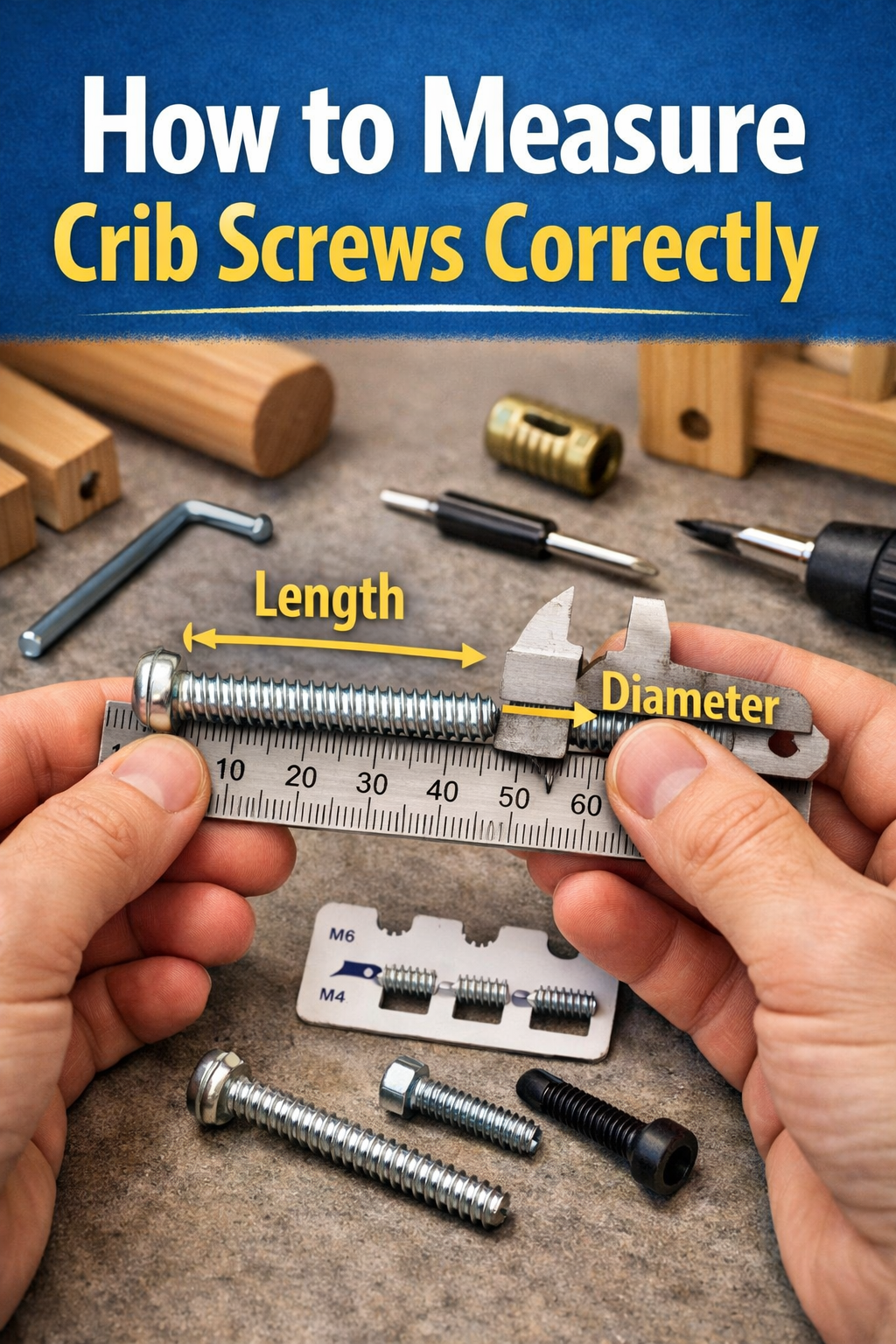

Visual Reference of Crib Screw Dimensions

Visual materials accompanying crib hardware listings typically illustrate length and diameter positioning without narrative direction. These visuals are used to clarify dimensional terminology used in product tables and specification sheets. The imagery functions as descriptive support for measurement values rather than as procedural material.

Common Variations Noted Across Crib Models

Across different crib brands and production periods, variation in screw dimensions is a common theme in manufacturer documentation. Even within a single model line, fastener lengths may vary depending on rail thickness, joint depth, or decorative trim. Documentation reflects these differences through discrete measurement entries rather than generalized sizing.

Thread format variation is also noted in crib records. While metric threading dominates modern crib manufacturing, some older models reference alternate formats depending on production location or supplier changes. These distinctions are typically recorded as technical notes within standards information rather than highlighted as functional differences.

Crib Hardware Identification When Original Screws Are Absent

Manufacturer materials frequently address scenarios in which original fasteners are no longer present by referencing comparative identification. In these cases, dimensional values from remaining hardware or documented specifications are used to categorize replacement parts. This approach appears in archival records and third-party parts catalogs as a method of matching specifications rather than prescribing action.

Model numbers and manufacturer labels are commonly cited as reference anchors in hardware documentation. These identifiers allow published measurement tables to be cross-referenced with crib production data. The emphasis remains on identification through recorded standards information rather than on procedural direction.

Related Crib Hardware Reference Pages

Additional pages that organize crib hardware information by classification include:

External Regulatory Listing Reference

For recall listings and regulatory records associated with crib hardware, published materials from the U.S. Consumer Product Safety Commission provide product notices and classification data. These records present standards information related to crib components without offering installation or modification instructions.

Summary

The phrase how to measure crib screws correctly functions primarily as a search shorthand for identifying dimensional specifications used in crib hardware records. Within published standards information, how to measure crib screws correctly appears as a labeling convention connected to size, thread, and head-style classification rather than as procedural content.

Across crib brands and model years, dimensional differentiation remains a consistent feature of hardware listings. The use of recorded measurements supports accurate identification within published specifications and archived parts catalogs. This page presents descriptive information only, reflecting how measurement terminology appears within manufacturer materials and regulatory listings.

When you click on links to various merchants on this site and make a purchase, this may result in this site earning a commission. This does not affect the price you pay.

UBGI Gold Standard 2026

Verified for performance, SEO,

and accessibility compliance.